How does pipe diameter impact flow rate, and why does it matter for your plumbing system? Understanding this crucial relationship is key to ensuring efficiency, reliability, and long-term performance.

Pipe diameter directly determines how water moves through your system. A pipe that is too small can create pressure problems, restrict flow, and lead to costly damage. Meanwhile, an oversized pipe might seem beneficial but often results in wasted energy and inefficiency. The right diameter strikes a balance, promoting smooth flow and reducing unnecessary wear and tear on your system.

By learning how pipe diameter affects flow rate, you can make smarter decisions, whether you are installing a new system or improving an existing one. Do not overlook this critical factor—it is the foundation of a well-functioning plumbing system.

Fundamentals of Flow Rate

Flow rate is the lifeline of any plumbing system, determining how efficiently water moves through pipes and reaches its destination. Defined as the volume of fluid passing through a pipe per unit of time, the flow rate is typically measured in gallons per minute (GPM) or liters per second (LPS). It is more than just a technical metric—it is a direct indicator of your plumbing system’s performance and reliability.

Pipe diameter plays a central role in controlling flow rate. Larger pipes accommodate more water, ensuring smoother and faster delivery, while smaller pipes restrict flow and can create pressure imbalances. Velocity is another crucial factor, as faster-moving water increases the flow rate, though excessive velocity can cause erosion and damage to pipes. Pressure differences within the system also drive water flow, with higher pressure improving efficiency and ensuring even distribution.

Optimizing flow rate is not just about convenience—it prevents common plumbing issues like backflow, uneven water pressure, and leaks. A well-maintained flow rate reduces wear on fixtures and pipes, extending the lifespan of the entire system. By understanding the principles of flow rate, homeowners and professionals can choose the right pipe sizes, materials, and designs for their plumbing needs.

A properly balanced flow rate ensures that water delivery remains consistent, efficient, and free of interruptions. Whether for residential, commercial, or industrial systems, mastering flow rate fundamentals safeguard the functionality and longevity of your plumbing infrastructure, saving time and resources in the long run.

Impact of Pipe Diameter on Flow Rate

The diameter of a pipe is far more than just a technical specification—it is a decisive factor that defines the efficiency, reliability, and overall performance of your plumbing system. The relationship between pipe diameter and flow rate shapes how water moves, how much energy is required, and how well your system endures over time.

Larger pipes create less resistance, allowing water to flow smoothly and evenly throughout the system. This reduces pressure drops and ensures consistent delivery, even to fixtures farther from the source. However, smaller pipes increase water velocity, which can lead to turbulence, noise, and stress on the system. This increased strain accelerates wear and tear on fittings, valves, and pumps, often leading to costly repairs.

Choosing the correct pipe diameter involves more than maximizing flow—it is about balance. Pipes that are too small force pumps to work harder, raising energy costs and reducing system efficiency. Conversely, oversized pipes can cause water to move too slowly, leading to sediment buildup and potential blockages. The right size minimizes resistance while maintaining adequate velocity for optimal performance.

A properly designed system with well-calibrated pipe diameters ensures durability, minimizes maintenance, and prevents inefficiencies. By understanding the interplay between pipe diameter and flow rate, you can make informed decisions that save time, money, and resources while maintaining a reliable, high-performing plumbing system for years to come.

The Role of Pressure in Flow Dynamics

Pressure is the driving force behind water movement in any plumbing system. It provides the energy needed to push water through pipes and overcome resistance. While often overlooked, pressure plays a critical role in shaping how effectively a plumbing system operates. Here is how it influences flow dynamics:

Driving Force for Flow

Pressure ensures that water flows efficiently through pipes, delivering it to fixtures without delay or interruption. Properly calibrated pressure maintains consistent water delivery and prevents performance issues.

Nonlinear Impact on Flow Rate

The relationship between pressure and flow is not direct. Increasing pressure improves flow, but not in a one-to-one ratio. This complexity highlights the need for balance when designing systems.

High-Pressure Risks

Excessive pressure puts unnecessary stress on pipes, valves, and fittings, leading to wear, leaks, or bursts. Maintaining pressure within recommended ranges protects the longevity of the system.

Low-Pressure Challenges

Insufficient pressure can cause weak water flow, making it difficult for water to reach fixtures in larger or more complex systems. Strategic adjustments are needed to maintain reliable delivery in such scenarios.

Interaction with Pipe Diameter

Pressure works in tandem with the pipe diameter to determine the flow rate. Smaller pipes with high pressure can lead to turbulence, increasing wear and reducing efficiency. Larger pipes may require more pressure to deliver water consistently across long distances.

Understanding the role of pressure in flow dynamics ensures plumbing systems operate effectively and remain durable over time. By calibrating pressure to match system design and needs, professionals can achieve optimal water flow while minimizing wear and energy waste.

Laminar vs. Turbulent Flow

In fluid dynamics, the distinction between laminar and turbulent flow is fundamental for understanding how water behaves within a plumbing system. These two flow regimes not only determine the efficiency of the system but also influence its long-term durability.

Laminar Flow

Laminar flow is smooth and orderly, with water moving in parallel layers that glide past each other. This flow type is common in systems with low flow rates or small pipe diameters. Because it minimizes friction and energy loss, laminar flow is ideal for applications where efficiency, quiet operation, and minimal wear on components are priorities.

Turbulent Flow

Turbulent flow is chaotic, characterized by swirling eddies and irregular movement. This regime occurs at higher flow rates and in larger pipe diameters. While turbulent flow increases energy loss due to friction, it can also help prevent sediment buildup and ensure consistent mixing in certain applications.

How Pipe Diameter Influences Flow Transition

Pipe diameter is a critical factor in determining whether water moves in a laminar or turbulent flow. Smaller pipes with lower flow rates are more likely to maintain laminar flow, as the reduced velocity discourages chaotic movement. In contrast, larger pipes often transition to turbulent flow at high velocities because the increased cross-sectional area promotes mixing and instability.

The shift between these regimes is governed by factors such as fluid velocity, pipe diameter, and fluid viscosity. While laminar flow offers efficiency and stability, turbulent flow may be preferred for systems that require strong flushing or debris clearance. Understanding how pipe diameter influences this transition ensures that plumbing systems are designed to optimize performance while minimizing unnecessary wear and energy loss.

By tailoring pipe size and system design to the desired flow regime, professionals can achieve a plumbing network that aligns with operational goals and long-term reliability.

Flow Rate for Efficient Pipe Sizing

Efficient pipe sizing begins with understanding the critical role flow rate plays in system performance. Flow rate, the volume of water moving through a pipe over time, is directly tied to pipe diameter, pressure, and velocity. Selecting the right pipe size ensures optimal performance while preventing unnecessary strain, inefficiencies, and costly repairs.

The relationship between pipe size and flow rate is governed by key principles. Larger pipe diameters allow greater water volume to move through with less resistance, reducing energy demands and pressure loss. Conversely, smaller pipes may restrict flow, increasing velocity and pressure, which can strain system components. Striking the right balance is crucial to maintaining long-term efficiency and reliability.

To calculate flow rate accurately, the formula Q=A×V is essential. Here, Q represents the flow rate, A is the cross-sectional area of the pipe, and V is the water velocity. Understanding this relationship helps professionals select pipe sizes that meet specific flow demands while ensuring energy efficiency and consistent pressure.

Modern tools like hydraulic software and online calculators simplify the process. These tools account for variables like pipe material, system pressure, and water velocity, providing precise data for informed decision-making. This level of accuracy is especially important for complex systems in commercial or industrial settings.

Efficient pipe sizing is not just about functionality; it is about creating systems that last. By focusing on flow rate and leveraging advanced tools, professionals can design plumbing networks that deliver consistent performance, minimize energy consumption, and withstand the test of time.

Practical Considerations in Pipe Selection

Selecting the right pipe diameter is more than a technical choice—it is a critical factor that determines the efficiency, reliability, and cost-effectiveness of any plumbing system. A well-chosen pipe diameter ensures that water flow meets the demands of the application without overburdening the system or causing inefficiencies.

The Impact of Pipe Diameter

Pipe diameter directly influences flow rate, water pressure, and system performance. Smaller pipes may suffice for residential systems, delivering adequate water pressure for daily needs. However, in commercial or industrial applications, undersized pipes can restrict flow, reduce efficiency, and strain components like pumps and valves. Conversely, oversized pipes might reduce velocity, leading to sediment buildup and unnecessary costs. Proper sizing strikes the balance between capacity and efficiency, ensuring consistent performance and durability.

Material Selection Matters

The material of the pipe is equally important. PVC is lightweight, affordable, and resistant to corrosion, making it a popular choice for low-pressure applications. Copper excels in durability and heat resistance, making it ideal for hot water systems, while stainless steel offers unmatched strength for high-pressure environments. The chosen material must complement the pipe diameter and suit the specific system’s needs, ensuring compatibility and long-term performance.

Cost vs. Longevity

Cost considerations often guide pipe selection, but focusing on upfront savings can backfire. While smaller pipes or less durable materials may lower initial expenses, they can lead to higher energy use, frequent repairs, and early replacement costs. Investing in the correct pipe size and material ensures long-term savings, improved performance, and fewer maintenance issues.

Installation Challenges

Installation constraints like space, weight, and labor requirements also play a role. Larger pipes may require specialized tools or additional labor, increasing the complexity and cost of installation. Addressing these challenges during the planning phase helps streamline the process and avoids costly delays.

Careful consideration of pipe diameter, material, cost, and installation factors ensures that the plumbing system operates at peak efficiency while minimizing long-term costs. Thoughtful pipe selection is not just a technical decision—it is the foundation of a plumbing system that delivers reliability and performance for years to come.

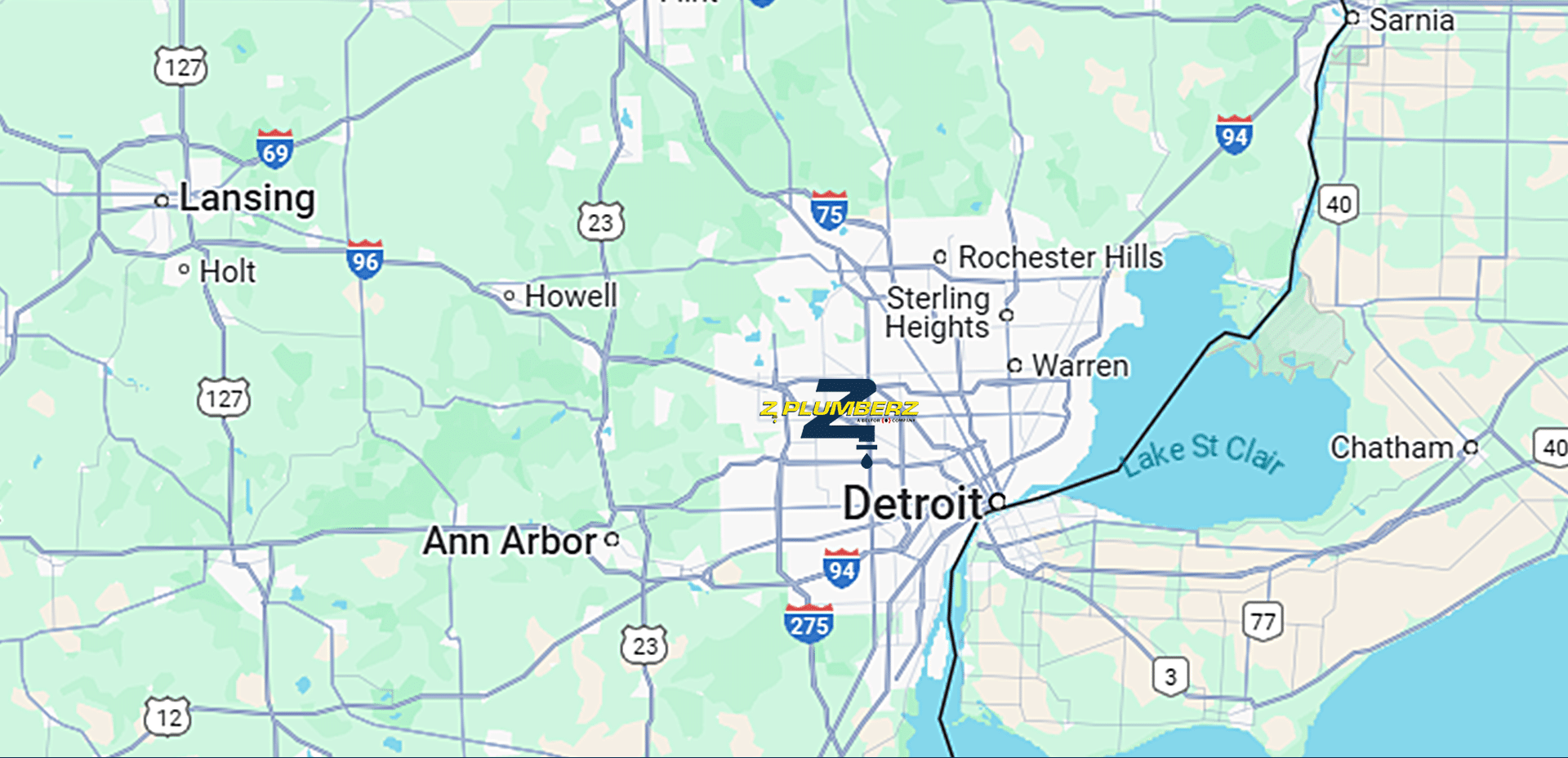

Seasonal Considerations in Davison, MI

December in Davison, MI, brings freezing temperatures that can pose significant challenges to plumbing systems. As water in pipes begins to cool, its flow rate decreases, and the risk of freezing rises. Understanding the impact of winter weather on plumbing can help homeowners avoid costly repairs and maintain optimal system performance throughout the colder months.

How Cold Weather Affects Plumbing

Freezing temperatures can cause water in pipes to expand, creating pressure that may lead to bursts or leaks. Pipes located in unheated spaces, such as basements, crawl spaces, and exterior walls, are especially vulnerable. Reduced temperatures also slow water flow, leading to inefficiencies in plumbing systems. These issues are compounded by inadequate insulation or poorly sealed spaces that expose pipes to cold air.

Steps to Maintain Optimal Flow Rates in Winter

- Insulate Exposed Pipes: Installing insulation around pipes in unheated areas is a simple yet effective way to prevent freezing and maintain consistent flow rates.

- Allow Water to Flow: Letting faucets drip slightly during freezing weather keeps water moving, reducing the likelihood of freezing and maintaining system pressure.

- Seal Gaps and Cracks: Sealing openings near pipes prevents cold air from entering and reduces the risk of freezing, protecting water flow integrity.

- Maintain Indoor Heat: Keeping interior spaces warm, even when away, ensures pipes remain at a safe temperature to avoid freezing and pressure buildup.

- Winterize Outdoor Plumbing: Disconnect hoses and drain outdoor pipes to eliminate standing water that could freeze and damage plumbing fixtures or pipes.

Plan Ahead for Cold Weather

Proactive measures help homeowners in Davison prevent plumbing issues during the winter months. Addressing potential vulnerabilities, such as exposed pipes or insufficient insulation, ensures systems operate efficiently despite freezing conditions. By preparing early, you can avoid the stress of plumbing failures and maintain consistent flow rates all winter long.

Contact Us Today

Are you tired of dealing with plumbing issues that disrupt your flow? At Z PLUMBERZ, we specialize in crafting plumbing solutions that deliver consistent flow rates, improved efficiency, and lasting peace of mind. Whether you are upgrading an outdated system or resolving a stubborn issue, we are here to help.

We do not just fix problems; we optimize your plumbing system to work better than ever. Our team combines advanced technology with years of expertise to ensure your system is tailored to your needs. From maximizing flow rate to improving system durability, we focus on results that save you time and money.

Stop letting plumbing frustrations take control. Contact Z PLUMBERZ today to schedule your consultation. Let us transform your plumbing system into one that works as hard as you do. With Z PLUMBERZ, you will enjoy reliability, efficiency, and a partner you can trust.

Frequently Asked Questions (FAQ)

-

Why is pipe diameter critical for determining flow rate?

Pipe diameter is one of the most significant factors affecting flow rate. A larger diameter provides a greater cross-sectional area, reducing resistance and allowing more water to flow. Smaller diameters restrict flow, increase velocity, and may create pressure imbalances that strain the plumbing system.

-

What are the risks of choosing the wrong pipe diameter?

Selecting an incorrect diameter can lead to serious issues. Pipes that are too small may cause reduced flow, increased pressure, and noisy operation, while oversized pipes may lower water velocity, leading to sediment buildup and inefficiencies. Both scenarios can result in higher maintenance costs and reduced system performance.

-

Can changing pipe diameter solve low water pressure problems?

While increasing pipe diameter can help maintain flow rate by reducing resistance, it won’t directly solve low water pressure issues caused by inadequate supply or poor system design. Pressure is determined by the force moving water through the system, not just pipe size.

-

How can I determine the right pipe diameter for my needs?

Choosing the right pipe diameter involves calculating the required flow rate and considering factors like pressure, water velocity, and the type of application. Using the formula Q=A×V, where Q is flow rate, A is pipe area, and V is velocity, helps in determining optimal size. For complex systems, hydraulic modeling tools or consulting with a professional ensures precision.

-

Does the pipe material impact the flow rate as much as the diameter?

Yes, pipe material affects flow rate by influencing internal friction. Smooth materials like PVC or copper allow water to flow more efficiently compared to rougher materials like steel. Combining the right diameter with an appropriate material ensures consistent flow and system longevity.